It's no secret. These days it's getting more expensive to run a business despite such overwhelming issues as supply chain problems, inflationary pricing, shipping capacity, and changing customer expectations. To stay competitive and profitable, you need to provide the products and services your customers need, but you must also find a way to do it efficiently and cost-effectively.

In this guide, we’ll dig into 6 ways you can save on your shipping and freight, consult a panel of industry leaders about how they do it, and add a few bonus tips at the end.

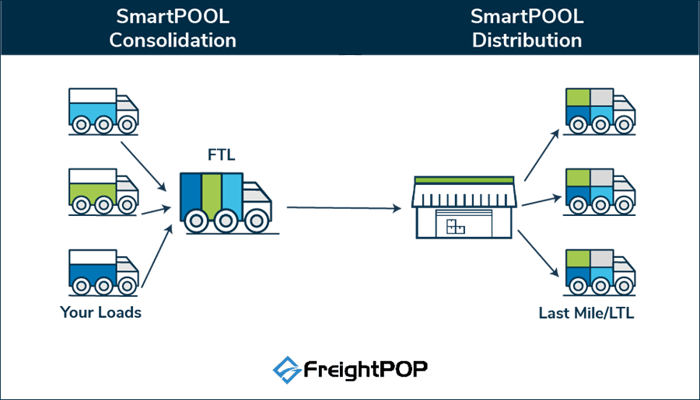

With freight pooling, shippers can consolidate multiple LTL and partial shipments for a more efficient way to deliver goods from multiple companies to a local pooling point. Once goods reach the pool point, freight is then sorted by final destination and sent for local delivery. How can this help with savings?

All Forward CEO Jonathan Ben Zvi explains:

Freight pooling can lead to significant savings by sharing transportation costs between multiple businesses, allowing companies to get better rates on shipping services.

Force by Mojio Ops Director Kyle MacDonald adds:

(Freight consolidation helps) boost efficiency, which in a time of supply chain issues and trucker shortages, is absolutely crucial.

Pros and Cons of Freight Consolidation

Freight pooling helps businesses save money in several ways, including:

- Reduced shipping costs by sharing costs

- Reduced damage due to less handling

- Lower fuel emissions

- Streamlined transit times

- Less crowded docks

By consolidating freight with other shippers, you can share in FTL rates rather than more expensive LTL rates.

YardsNearMe Cofounder, Alex Haley, points out that:

Freight pooling is extremely helpful for cutting the operational cost to a great extent. In this procedure, the carrier generally consolidates multiple shipments to transport. In most cases, for this purpose, we use a localized pool unit for transport purposes. Therefore, the cost is minimized significantly.

Conex Boxes Cofounder, Teri Shern, says pooling is not just about money:

Aside from saving money, freight pooling creates a much more efficient shipping process...you’ll be less likely to run into issues for your business, you can create a better customer experience (such as including check-in points to track delivery), and much more.

The 3PL's Academy Logistics Consultant & Freight Agency Investor, Jaspal Singh, says pooling does not only benefit the shipper:

If a carrier sets up their logistics operations correctly, their methods can cut costs down and simultaneously add revenue to the cost per mile. This is what makes freight pooling a win - win for all parties. Carriers can use their method to truly become the customer solution for distributors, shippers, and receivers alike.

There are some downsides to freight pooling that shippers should take into consideration.

For example, freight pooling:

- Requires more communication and coordination

- Typically requires shorter leads times on shipments

- Does not work as well for reverse logistics

Many companies' biggest challenge with freight pooling is that they lack the infrastructure, expertise, or time to coordinate pooling. You will need intelligent enterprise logistics tools to optimize the planning, execution, and workflow to efficiently manage all of the complexities.

2. Trade Secrets to Get the Best Freight Rates

Transportation Management Systems

Similar to how airlines operate, some carriers offer better pricing for certain legs of a trip than others. You can often save thousands of dollars by combining carriers, adding or switching lanes, or adjusting service levels.

An example of this is seen with FreightPOP's FreightRateHACKER, which uses algorithms to sort through carrier data to isolate the optimal routing for cost savings. This is a feature of their transportation management system (TMS).

TMS systems should help you find savings by giving you the data you need to negotiate quotes better by:

- Cross comparing spot quote rates against negotiated rates and carriers

- Integrating carrier websites and emails into one platform

- Contacting multiple carriers in a single action

- Bringing all carrier responses and bids into one platform, with side-by-side comparisons for your review

- Enabling real-time acceptance and response to carriers

FreightPOP's Strategic Partnerships Manager, Jon Freeman, explains a TMS' intrinsic value to high volume shippers:

Retail giants have changed our expectations of how fast a product can arrive and in our microwave society, we’re demanding free shipping, next day, or two-day at best. This puts an enormous amount of strain on a company's supply chain cost center as they try to keep up with growing demand.

This is forcing companies...to shift their view of their transportation process to more of a value driver, rather than another cost line item. To do this, companies have to be SURE that they are shipping on the lowest rate, with the most optimized route, with the most streamlined quoting and shipping processes, every time. Without a scaling enterprise Transportation Management System, this is impossible.

Optimizing the Last Mile

Conex Boxes' Shern points out that:

Another way that you can save on shipping and freight is by optimizing the final-mile process.

The last mile of delivery accounts for more than half of your total shipping costs. The last mile typically requires more complex routing, more idle time, more stops, and more time on the road. Even minor efficiency improvements can yield significant savings.

Solving the last mile optimization challenge is why companies with brick-and-mortar stores use their retail stores for last mile distribution rather than centralized warehouses, especially for same-day or next-day delivery. Walmart, for example, plans to increase its delivery capacity by a third in 2022, using its local stores to handle fulfillment to reduce last-mile costs.

Target is opening up ten sorting centers as part of its solution, with trucks collecting items from stores throughout the day, sorting them by zip codes, and sending them to delivery partners. The effort avoids palletizing items at individual stores and breaking them apart for redistribution.

Last-Mile and Dynamic Pricing

Another challenge on the horizon that will impact last-mile logistics is dynamic carrier pricing. UPS is a perfect example of this. After rolling out its Dynamic ORION, a platform that optimizes routes using AI and algorithms, experts predict it is just a matter of time until they incorporate dynamic pricing, much like how Uber and Lyft price rides.

Dynamic pricing will make it impossible to determine last-mile costs manually. In the near future, a scalable TMS system will be imperative to stay on top of pricing technology.

Zone Skipping

Another strategy for reducing costs is zone skipping. With zone skipping, you bypass the charges carriers apply to packages traveling over established zones. There can be significant savings by skipping zones and having packages arrive within the last-mile.

Zone skipping requires careful planning by shippers to combine as many pallets and packages as possible to particular regions through a single FTL or LTL load. Besides saving money, zone skipping also reduces handling as cargo is unloaded and reloaded at various hubs and distribution centers, which reduces breakage and helps maintain tighter delivery times.

For smaller retailers and growing businesses, this can be a smart solution.

Retail and E-commerce Expert, Meaghan Brophy, says:

on the horizon that will impact last-mile logistics is dynamic carrier pricing. UPS is a perfect example of this. After rolling out its Dynamic ORION, a platform that optimizes routes using AI and algorithms, experts predict it is just a matter of time until they incorporate dynamic pricing, much like how Uber and Lyft price rides.

Using zone skipping to get packages to local USPS centers (for example) and then utilizing USPS for last-mile delivery, can be a great way to save shipping time and costs.

Expand Searches to Overseas Shippers

Sometimes, you may find better rates by working with shippers in other countries directly.

Old Bull Lee founder, Lee Johnson, says:

We find shipment orders that originate from countries that are not as economically strong as the US end up being overall significantly cheaper. I can not tell you exactly why, I do not think it is as simple as a reduced cost of labor.

I think there is also some default recognition that companies from the US are often financially strong and all the downstream shippers and entities associated with your parcel's transport somehow seem to recognize that and that becomes an opportunity to attach a premium of sorts to the transportation of goods. Freight is very complicated, with many people associated with it, so I can not explain exactly why this is true, I just know that if we have our shipping set up from outside the United States it is almost always less expensive.

Digitizing logistics has been a hot topic for a few years now. 3PL Academy's Singh theorizes that:

Right now, we are transitioning into a sellers’ market. Consumers are spending/purchasing in unprecedented numbers. Freight is opening up in ways we have never seen before. Distributors are having to strategize in order to keep products flowing since there are so many problems arising.

Reducing manual tasks and data entry should be near the top of your list to improve efficiency and reduce costs. A smart TMS platform that enables automation is your best friend. Any place you can automate your operation can improve your efficiency and reduce errors. These efficiencies save money in multiple places throughout the entire freight shipping lifecycle.

The right automation systems lower overhead costs while making everything happen more quickly and seamlessly.

All Forward's Zvi explains that:

To keep our supply chain running, we embraced automation to eradicate human data-entry errors, helping us boost our overall efficiency.

To optimize your efficiency, you need a robust TMS. If you are still using an in-house or legacy system or are still doing many tasks manually, it's time to upgrade. However, keep in mind that not all TMS automation tools are equal.

For example, how many of these functions are you currently automating?

- Tariff rate management

- Carrier rate management

- Accessorial fee management

- Sales order management

- Customer shipping notifications

- HAZMAT air and ground documentation

- Multi-leg shipping

- NMFC management

- Returns processing management

- Lowest quote shipping compliance

Another area where automation can play a big role and deliver savings is freight claims management and timeline notifications. Shippers often leave money on the table because of the paperwork and time involved in claims. With the right TMS, you can improve your ability to file claims. It can also help you evaluate carrier performance as part of your overall assessment beyond just price points.

By automating critical processes, shippers of all sizes see measurable improvements in workflow, which translate into savings. For example, a modern TMS allows you to see:

- Real-time freight rates

- Real-time tracking

- Customized reporting and analysis

If you’re comparing transportation management systems, here are 9 questions you need to ask to get the right one for your business.

No matter how efficient you are, invoice exceptions occur. Late shipments, lost shipments, and wrong rates and accessorials get charged. Freight auditing is crucial, yet many companies often skip this step and leave money on the table.

Carriers don’t always make it easy for you to compare quotes to shipment, so often, areas where you could make a claim get lost in the shuffle. There’s money in freight audits. Using electronic data interface (EDI) invoicing, you can automate the process to bring all of your invoices into a centralized platform for greater visibility and auditing.

When you consider that between 5% to 10% of all deals do not meet delivery requirements, the savings can add up quickly when you conduct freight audits. You need a system that can automatically conduct audits, searching for things like:

- Duplicate charges

- Inaccurate NMFC codes

- Rating errors

- Incorrect weight

- Accessorial fee errors

- Applicable tax applied correctly

- Unapplied discounts

How Much Can You Save with Freight Audits?

FreightPOP's audit feature typically provides customers with a minimum savings of 15% on their shipping costs from regular audits. For shippers organizing 500 freight deliveries a month, that can lead to more than $18,000 a month in savings!

As Zero Down Supply Chain Solutions CEO Brad McBride shares, you'd be amazed what you can find through thorough audits. One client audit revealed they weren't getting a discount they had earned from a parcel provider, leading to more than $80,000 in overcharges previously unnoticed

Good, Better, Best Auditing

McBride drives the point home on auditing by advising:

Whether you audit through TMS matching and have your staff handle the exceptions with carriers, or outsource to a third party such as a trusted partner like FreightOptics, you need to be conducting freight audits on every single shipment.

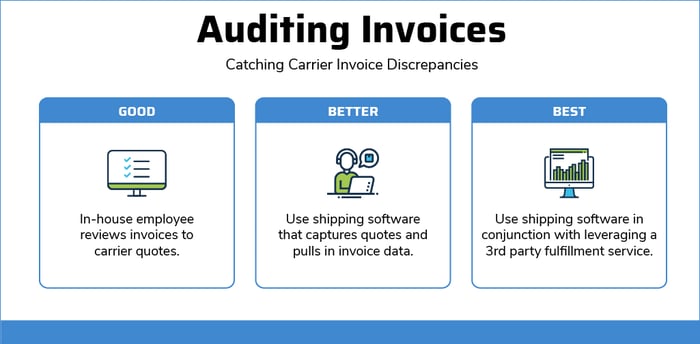

You really only have three options when it comes to auditing:

Good - Attempting to audit in-house via an employee manually comparing quotes to invoices.

Better - Using shipping software (aka TMS) to catch errors digitally and then designating a staff member to follow-through on exceptions.

Best - Combining your TMS data with follow-through by a 3rd party company to manage exceptions and deal directly with carriers on your behalf.

Whatever you commit to, just make sure to audit!

One of the biggest concerns for just about everyone involved in logistics over the past few years has been dealing with supply chain disruption. It’s caused delays, massive increases in pricing, and volatile capacity in shipping.

While there's been some easing at the ports, analysts aren't expecting it to return to pre-pandemic levels anytime soon. The International Money Fund says ongoing supply chain problems are one of the primary reasons it has downgraded its forecast for economic growth globally for 2022 from 4.9% to 4.4%.

China is still dealing with lockdowns, limiting shipping options. EU and US ports are still coping with backlogs. Rail boxes are sitting for more than six days to get on a train, Gene Seroka, Executive Director of the Port of Los Angeles, told CNBC. “That’s triple the dwell time compared to pre-pandemic.”

According to MarineTraffic and Blume Global data, vessels at the Port of Oakland take six days to unload. Import containers sit for nearly 11 days before being transported. At the Los Angeles Port, it’s taking 12 days for containers to ship out. Similar backups have hit the ports of New York and New Jersey.

As we’ve all learned the hard way, delays, backups, and tighter capacity drive prices up for everyone.

Optimizing Logistics and Scenario-Planning

Managing your entire supply chain from end to end is vital. It requires optimizing your logistics at every step and staying on top of changing consumer habits to plan more efficiently.

YardsNearMe's Haley advises:

If you want to succeed in this situation, you must work on the consistent changes as per the changing scenario in consumer behaviors. For supply chain management, we start with scenario-planning strategies. Then, we look closely at the demand environments and mitigate the arising issues in our strategic planning. After that, we make new plans and change our strategies based on the changing consumer demands.

Consider Multiple Suppliers and Shippers

Ever Wallpaper Cofounder, Luke Lee, recommends:

Consider using multiple suppliers for different components of your product. This can help to reduce the impact of any disruptions at one supplier.

The same can go for shippers. When capacity is tight, you may need to expand your carrier or broker network to ensure you have the capacity you need.

With the volatility in the supply chain, backups at the ports, and the shortage of trucks and drivers, these options also make it much easier to put contingency plans in place in case of major disruptions.

Managing Relationships

Managing your carrier, vendor, and customer relationships creates a more collaborative approach. These relationships can become even more important during times of disruption. In today's world of email and automation, don't forget that relationships are still meaningful.

3PL Academy's Singh shares:

The advice I wish someone would have given me when I first started over 10 years ago is to always remember that this is a people-based business. We value long-term relationships with our suppliers, which enables us to communicate effectively and avoid disruptions.

Relationships allow more candid discussion when disruptions occur. When you can help each navigate through challenges, you build trust, which can become essential when you need to adjust.

Ever Wallpaper's Lee adds:

(When you) establish good relationships with your suppliers, this can help to ensure that they are willing to work with you to resolve any issues that arise.

Ever Reach Logistics' Lisa Baron-Croft adds:

Too often, people fail to take the time to build relationships with truckers, brokers, shippers, and receivers. They don't make an effort to make personal connections, which can hinder you in the long run

A lot can go haywire with freight. A load cannot be delivered as expected, unexpected storage is needed, or a trucker is expected to hold a load and sit on making any movements. You are more likely to negotiate a workable situation for all involved if you have a solid relationship with those people.

Re-evaluate Profitability

On re-evaluating profitability, 3PL Academy's Singh says:

Capacity and knowledge is a major concern to the supply chain. The key is to build your business to be the solution to what's profitable to you in the supply chain.

You may need to make some difficult decisions about where you get supplies and products, how you ship and deliver, and the end customers you do business with. As supply chain disruptions have created havoc in pricing, you may find some products are no longer generating the revenue you need to keep healthy profit margins.

Singh adds:

Start designing projects specifically for the supply chain and running those projects in conjunction with your operations management tools and systems.

Business intelligence (BI) in freight means you must capture your logistics data, analyze it, and use insights to inform your future strategies and decisions.

YardsNearMe's Haley discusses the value of business intelligence in logistics:

Business intelligence is essential for understanding the shipping and logistics industry. It can provide insights into trends, patterns, and customer behavior. This information can be used to make decisions about pricing, routing, and other aspects of the shipping process. Business intelligence can also help to identify potential problems.

As we've learned, things can change quickly in the freight business. You must have a way to adjust rapidly to changing conditions. Business intelligence (BI) is key to developing and maintaining an agile approach. BI is not an optional tool in logistics anymore; it is an essential component for managing and growing your business.

Singh adds:

When you use your knowledge to create structure, you can gather much more valuable and pertinent information which can set you apart from your competitors. We can now start to build systems to our intelligence and with those systems expand our companies because we can now handle more volume.

BI can identify more efficient routing, bottlenecks in the supply and delivery chain, pricing discrepancies, and opportunities for cost reductions. By setting up key performance indicators (KPIs) and data visualizations, you can keep track of your key metrics at a glance using a modern TMS. Logistics software reduces the time to create and manage reports while retaining the ability to drill down to any specific area you want to examine further.

BI gives you the knowledge you need to make smarter business decisions. According to a study by Deloitte, companies that make business decisions based on data intelligence are 77% more likely to achieve their business goals.

Detailed Analysis

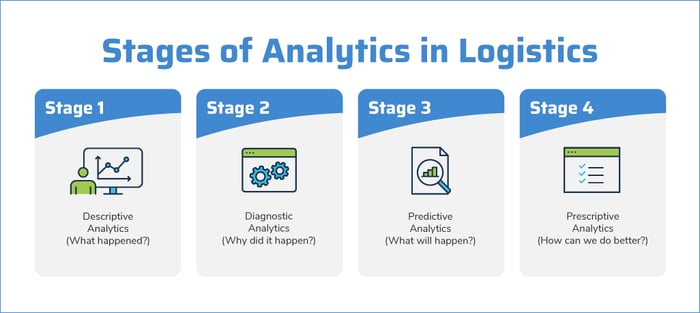

The right TMS can also help you leverage AI for the four types of analytics:

- Descriptive analytics

Understand what’s happening and where you can optimize operations for cost efficiency. - Diagnostic analytics

Understand why something happened to avoid similar mistakes or missed opportunities in the future. - Predictive analytics

Run what-if scenarios to see the impact of making adjustments to your shipping and logistics. - Prescriptive analytics

Advanced analytics that can recommend areas for cost improvements.

Singh says:

Overall, the value of intelligence in this industry is peace of mind.

BI provides that peace of mind by ensuring you are using the most efficient and cost-effective models. Combining robust reporting with real-time data allows you to analyze each step in your shipping process to ensure best practices. It can also identify areas that need improvement.

Here are some ways shippers are using business intelligence to streamline their business and save money on freight.

Evaluating Projects and Products

The details are in the data. Smart shippers are using logistics data as they evaluate projects and products.

Hayley says:

(Data) helps us have greater control over the strategies we plan for a specific project. (Leveraging BI), we can also assure the volume of data we gather for the particular project, and then we proceed to work further.

Analyzing Shipping Modes

It’s easy to fall into patterns and use the same shipping methods or carriers every time. However, you should routinely review options to see if there are savings opportunities. Examining your historical data can also put you in a better position to negotiate future shipping rates.

There are other ways to save on your shipping and freight costs. Here are six more tips to consider.

1. Pay Attention to Packaging

Ever Wallpaper's Lee recommends paying close attention to packaging:

Damaged goods are not only costly to replace, but they can also lead to delays in transit. Well-made packaging will not only protect your products, but it can also help them to arrive at their destination on time.

You do have to be careful about over-packing, though. Over-packing can add volume and weight. Talk to your carrier about reducing dunnage and potential ways to reduce your overall packaging to get better dimensional weight pricing.

2. Contract Steady Lane Volume

Steady lane volume allows carriers to market backhauls and build a network that can ultimately reduce costs and help you build stronger relationships. The latter of which is crucial when capacity is tight.

3. Ship Off-Peak

If you have flexibility, look at surrounding dates by booking your shipments. Moving your ship and delivery dates a day or two forward or backward can yield savings. Mondays are typically low-volume days in most industries. Fridays also tend to be lighter as retailers want goods in-store before the weekend starts.

4. Negotiate Delivery Times

When negotiating purchase orders, consider negotiating delivery times as well. The farther out in the future you can plan, the easier it will be to find better pricing. This advance notice gives shippers more time to line up resources.

5. Improve Your Load Time

Wait time on location is a profitability killer for carriers. When you can consistently deliver on time and have fast load times, you'll get more favorable considerations from shippers. For example, you may get better rates if you can guarantee load times within a one-hour window rather than the typical two-hour window.

6. Offer Later Pick Up Times

Another strategy that can lead to cost savings is offering later pick-up times. Carriers might turn down an afternoon load, for example, because it conflicts with another run. You can allow the carrier to complete their deliveries with later pick-up times and then use your loads for backhaul.

FreightPOP Streamlines Your Operation and Uncovers More Hidden Ways to Save Money

FreightPOP provides one-click logistics, providing end-to-end management of all your shipments.

With FreightPOP, you get integrated, flexible capabilities to manage your logistics infrastructure that encompasses the entire Shop, Ship, Track, Audit, and Analyze ecosystem, including:

- Accessing the best freight rates and comparing all shipping modes in one place

- Tracking every inbound and outbound

- Leveraging automation and shipping audits to help uncover hidden savings

FreightPOP also provides robust reporting and AI-enabled analytics to provide you with the business intelligence you need for better decisions.